MTS Motor

Payplok

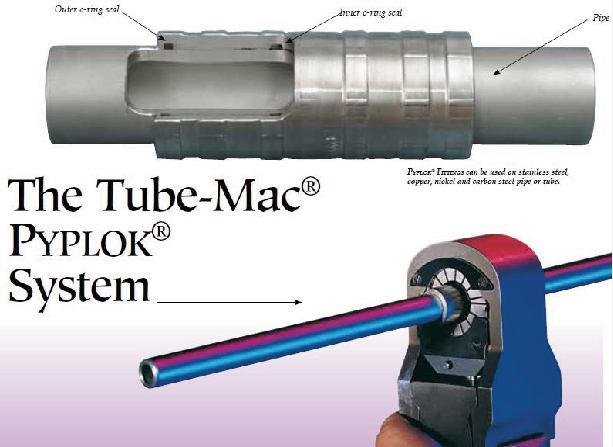

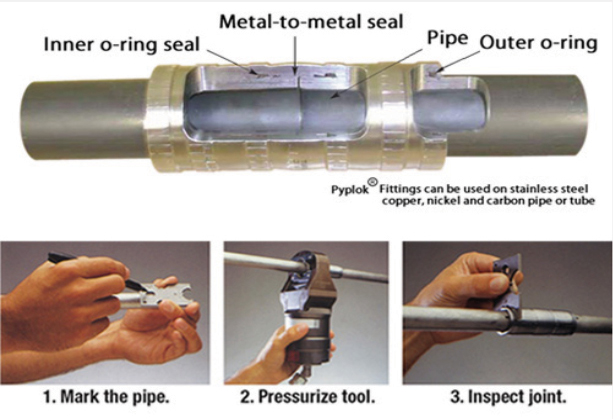

PYPLOK® is a 360° radial swage mechanically attached fitting which permanently connects pipe and tube for a leak free, cold connection.

The system is fast, reliable and tamper proof ideal for use in new build and maintenance works where fire hazards exist and a clean piping connection is required.

A hydraulically powered compression tool swages the fitting over pipe/tube plastically deforming the fitting in seconds.

The fitting can be used in a wide variety of low to high pressure piping applications in industries such as Marine & Offshore, Navy, Oil & Gas, Petrochemical, Steel, Mining and other Industrial uses.

They Offer :

- The Tube-Mac PYPLOK® Mechanically Attached Fitting System is the best alternative to threaded, welded, or brazed joints. The PYPLOK® system incorporates an external swaging process as a way of joining pipe ends together. The external radial swaging process compresses the fitting onto the pipe or tube, which results in a permanent, leak-tight joint.

- There is no need to purge or flush the piping system of gas or liquid because the application of PYPLOK® requires no hot work. In other words, PYPLOK® allows for a "cold system".

- The time required to join the pipe ends together is significantly shorter because of the portable tools used to compress the fitting onto the pipe.

- Reduced inspection time through a go-no-go gauge, which checks for proper swaged diameter to determine satisfactory compression of the fitting. This eliminates the need for conventional NDT requirements such as X-rays etc.

- There is no need for fire watch or any special fire permit which are needed for welding or brazing, as there are no fumes or fire hazards when using the PYPLOK® application.